Products

Our Products

Our Product Range

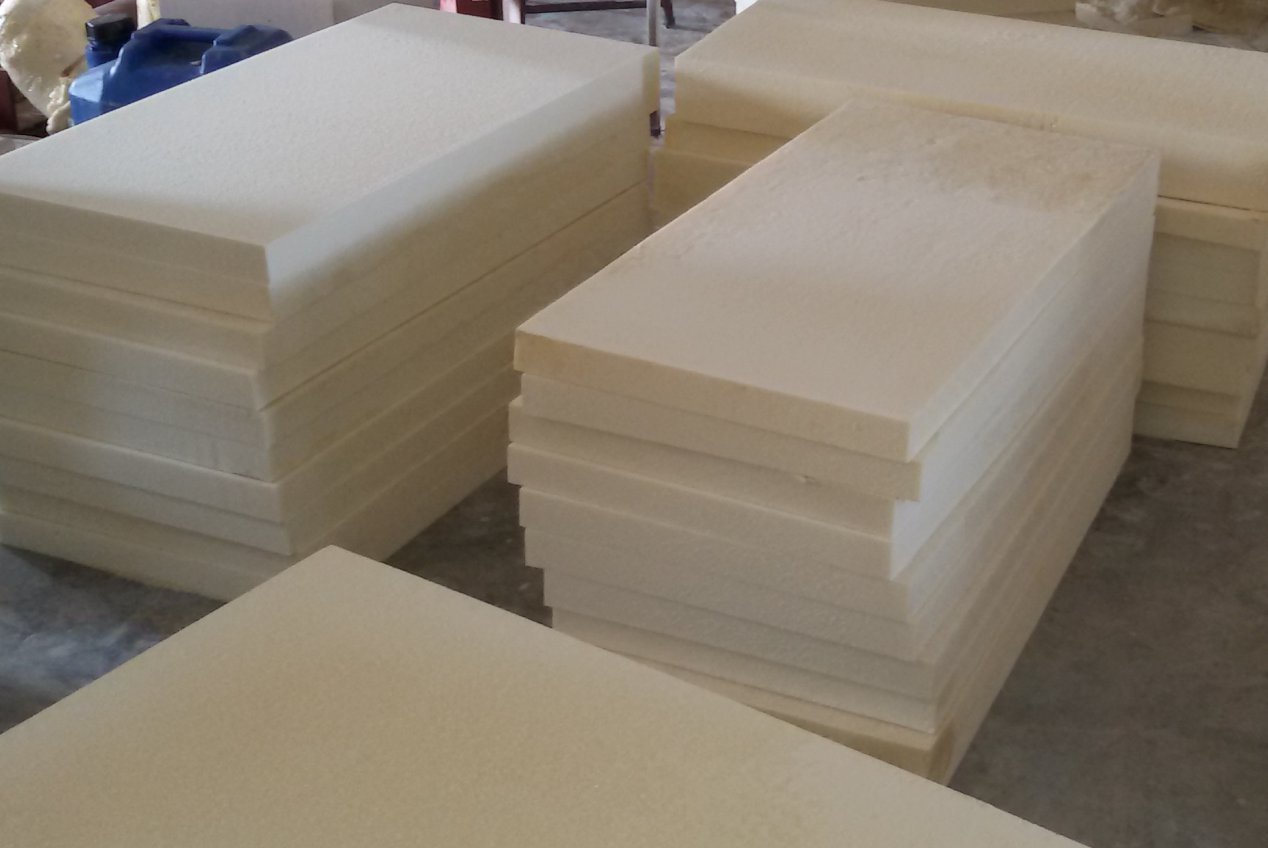

PUF/PIR Slabs

Available in various thicknesses with self-skin or a wide range of materials. Our slabs, typically 1 MTR x 0.50 MTR, offer exceptional thermal efficiency for diverse applications.

PUF/PIR Pipe Sections

Manufactured to required densities for pipe sizes from 15 NB to 800 NB, complete with craft paper. Designed for optimal insulation of industrial pipelines.

PUF/PIR PIPE SUPPORTS

Custom-made with densities from 100 Kg/m³ to 300 Kg/m³ for round pipe sizes from 15 NB to 350 NB, ensuring structural integrity and thermal continuity.

In-Situ PU Foam Insulation

We provide large-scale, on-site PU Foam Insulation services, ideal for complex structures, irregular surfaces, and specialized buoyancy applications.

Polyisocyanurate (PIR) dual Insulation

We manufacture all the above mentioned products with POLYISOCYANURATE Polyisocyanurate (PIR) suitable for the dual Insulation

Sandwich Panels for Cold Storage

PU FOAM pre-fabricated sandwich panels are available in a variety of heights and widths for applications including walls, floors, doors, frames, door plunges, tee walls, corners, and ceilings.

Polyurethane Foam (PUF) Characteristics

Our PU Foam is a highly efficient insulating material, known for:

High Mechanical Strength: Light in weight yet rigid and sturdy, structurally strong & dimensionally stable, with high compressive and flexural strength.

Economical: Features the lowest ‘K’ value among insulating materials, offering high moisture resistance, permanent and long-lasting insulation, and significant electricity savings.

Easy to Apply: Simple to handle and quick to install, easily cut by saw or sharp knife, boasts excellent adhesive properties, and resists soaking, swelling, or buckling in moisture.

Longer Life: Exhibits high aging resistance, does not attract rodents or pests, is odorless and does not absorb odors, remains unaffected by seawater, and does not harbor fungi, mildew, or spores.

Rigid polyurethane foam is the most efficient insulating material, formed by two chemicals’ component reaction. The material expands in a matter of seconds and within few moments later becomes a CLOSED CELL RIGID INSULATING MATERIAL. The superior insulating ability of PU FOAM is due to the presence of an inert gas trapped in micro tiny cells. These cells inhibit heat transfer.

Typical and Mechanical Properties of Rigid PU Foam

| Property | Unit | Result |

|---|---|---|

| Standard Density | Kg/M³ | 36 ±2 |

| (Other densities available on request) | ||

| Compressive strength | Kg/M² | 1.2-2.1 |

| Closed cell content | % | >90 |

| Thermal conductivity | W/m°K | 0.05 |

| Dimensional stability | % | ±1.0 |

| Water vapor permeability | ng/Pa.s.m | 2.9 |

| Water absorption (7 days) | % vol | <1.0 |

| Fire resistance | Self extinguishing | |

| PIR Grade | Available on request | |

| Service temperature range | °C | -200 to +110 |

| Facing | GI / Aluminum / Bitumen / Kraft Paper / Fiber Glass / Asbestos / Poly Coated Paper | |

| Size | 1m x 0.5m | |

| Thickness | mm | 25mm to 100mm |

| Other thickness & dimensions | Available on request |