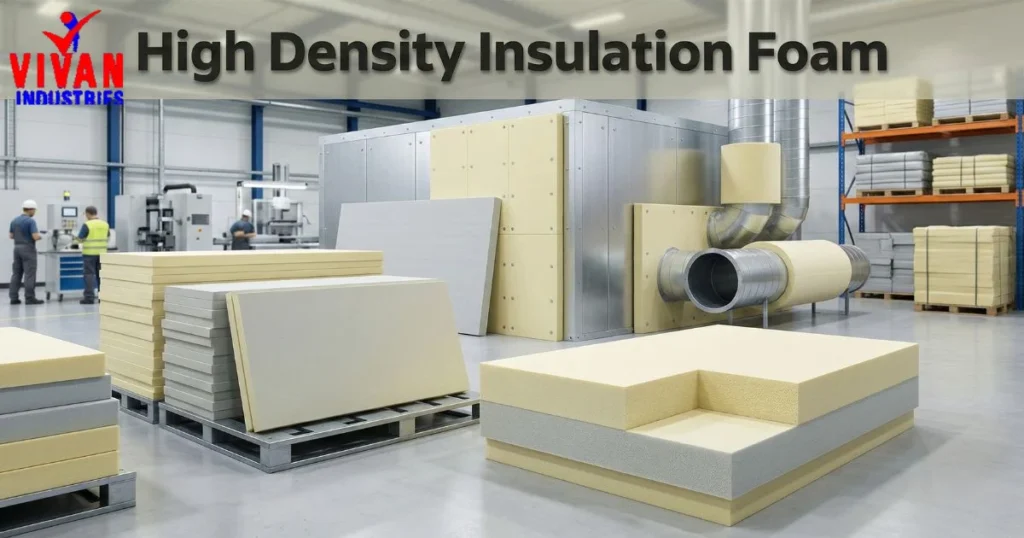

In 2026, construction success is measured by energy efficiency, durability, and sustainability. One material consistently outperforming traditional insulation is High density insulation foam. From modern homes to large-scale industrial projects, this advanced insulation solution is helping buildings meet stricter energy codes while lowering operational costs.

At Vivan Industries, insulation innovation meets real-world performance. As a recognized name in insulation solutions, the company delivers products designed to meet future-ready building standards. This pillar guide is crafted to help you fully understand High density insulation foam, its benefits, applications, and why choosing the right supplier directly impacts SERP-ranking construction decisions and real-world efficiency.

What Is High Density Insulation Foam?

High density insulation foam is a rigid insulation material manufactured with a tightly packed cellular structure. The higher density improves thermal resistance, mechanical strength, and moisture control when compared to conventional insulation materials.

Unlike low-density foams, it:

- Maintains shape under heavy loads

- Offers consistent insulation over decades

- Performs well in extreme temperatures

Because of these advantages, High density insulation foam is widely used in structural insulation where long-term reliability is critical.

Why High Density Insulation Foam Is Critical in 2026

Building regulations worldwide are tightening. According to recent energy efficiency data, buildings consume nearly 40% of global energy, pushing governments to enforce higher insulation standards.

High density insulation foam plays a key role by:

- Reducing energy loss by up to 45%

- Supporting net-zero and passive building designs

- Meeting updated fire and safety norms

Types of High Density Insulation Foam

High Density Polystyrene Foam

High density polystyrene foam is lightweight, cost-effective, and widely used in both insulation and packaging. Its uniform structure ensures stable thermal performance.

Key advantages:

- Consistent insulation value

- Easy handling and installation

- Suitable for walls, roofs, and floors

High Density Extruded Polystyrene

High density extruded polystyrene is produced using an extrusion process that enhances compressive strength and moisture resistance.

Ideal for:

- Basements and foundations

- Cold storage units

- Industrial flooring

Both types fall under the broader category of High density insulation foam, offering flexibility based on structural and environmental needs.

Technical Properties and Performance Metrics

| Property | Value |

| Thermal Conductivity | Very Low |

| Compressive Strength | High |

| Moisture Absorption | < 1% |

| Service Life | 30–50 Years |

These characteristics explain why High density insulation foam consistently outperforms traditional insulation in long-term applications.

Applications Across Residential, Commercial, and Industrial Sectors

High density insulation foam is engineered for versatility:

- Residential: Roofs, cavity walls, floors

- Commercial: Office buildings, malls, hospitals

- Industrial: Warehouses, manufacturing units

- Cold Storage & HVAC: Temperature-sensitive environments

This wide applicability makes it a preferred insulation choice for developers aiming for both compliance and performance.

Benefits of High Density Insulation Foam for Long-Term ROI

Using High density insulation foam delivers measurable advantages:

- Energy Savings: Reduced heating and cooling costs

- Structural Stability: Handles heavy loads

- Moisture Protection: Prevents condensation and mold

- Low Maintenance: Long lifespan with minimal upkeep

When sourced from a trusted High density insulation foam Manufacturer in Gujarat, performance consistency is guaranteed.

Sustainability, Energy Codes, and Green Building Compliance

Sustainable construction is no longer a trend; it is a requirement. High density insulation foam supports:

- LEED, IGBC, and GRIHA certifications

- Reduced operational carbon emissions

- Improved indoor air quality

Modern formulations use eco-friendly processes, making insulation safer for both occupants and the environment.

How to Choose the Right High Density Insulation Foam

Before selection, evaluate:

- Required R-value

- Load-bearing requirements

- Moisture exposure level

- Local energy regulations

Working with a reliable High density insulation foam Supplier in Gujarat such as Vivan Industries ensures correct product matching and technical guidance.

Importance of a Reliable Manufacturer and Supplier

Not all insulation is created equal. A dependable High density insulation foam Manufacturer in Gujarat provides:

- Strict quality control

- Consistent density

- Compliance with IS and international standards

Vivan Industries also stands out as a trusted High density insulation foam Supplier in Gujarat, serving infrastructure, industrial, and commercial projects across India.

Why Vivan Industries Is a Trusted Industry Leader

Vivan Industries has built its reputation on:

- Advanced manufacturing technology

- Customer-focused solutions

- Reliable supply chain support

By delivering premium High density insulation foam, the company supports energy-efficient construction and long-term building performance nationwide.

How to install High density insulation foam correctly:

- Prepare a clean, dry surface

- Measure and cut insulation boards accurately

- Fix using approved adhesives or fasteners

- Seal joints to prevent thermal bridging

Correct installation ensures maximum insulation efficiency and durability.

Cost Comparison and Performance Analysis

| Insulation Type | Initial Cost | Energy Efficiency | Lifespan |

| Fiberglass | Low | Moderate | 15–20 yrs |

| Mineral Wool | Medium | High | 20–25 yrs |

| High Density Insulation Foam | Medium-High | Very High | 30–50 yrs |

Despite a slightly higher upfront cost, High density insulation foam delivers superior ROI through energy savings and longevity.

Future Trends and Market Outlook

The insulation market is evolving rapidly. Key trends include:

- Smart insulation systems

- Recyclable foam materials

- Enhanced fire-resistant technologies

Companies like Vivan Industries are investing in innovation to stay ahead of future building demands.

Conclusion

High density insulation foam is the backbone of modern, energy-efficient construction. Its performance, durability, and sustainability benefits make it the smartest insulation investment for 2026 and beyond. Partnering with Vivan Industries ensures access to high-quality insulation solutions backed by expertise and innovation. If you want better energy savings, stronger buildings, and long-term value, High density insulation foam is the clear choice.

FAQs

What makes high density insulation foam better than traditional insulation?

It offers better strength, lower thermal loss, and longer service life.

Is high density insulation foam suitable for Indian climates?

Yes, it performs well in both hot and cold conditions.

How long does it last?

Up to 50 years with proper installation.

Is it environmentally friendly?

Modern production methods reduce environmental impact.

Where can I buy reliable insulation in Gujarat?

From a trusted supplier like Vivan Industries.

Follow US: Facebook, Instagram

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.